When working with fluid systems, one of the most fundamental decisions you’ll face is whether to use tubing or pipe fittings—especially when dealing with stainless steel fittings. This choice impacts everything from system performance and longevity to installation costs and maintenance requirements.

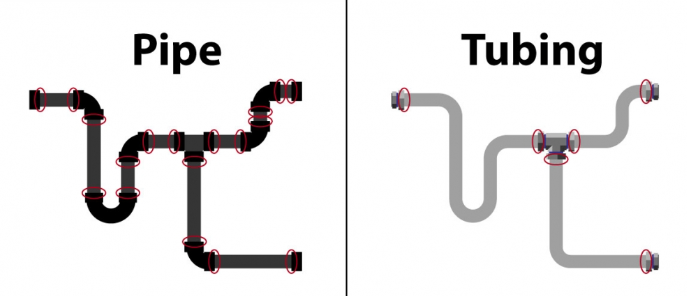

Before comparing fittings, it’s essential to understand the basic differences between tubing and piping:

- Tubing is typically specified by its outside diameter (OD) and wall thickness

- Piping is generally identified by nominal pipe size (NPS) and schedule (wall thickness)

- Tubing often has tighter tolerances and smoother surfaces

- Piping is more standardized for high-pressure applications

Key Considerations for Choosing Stainless Steel Fittings

1. Application Requirements

Stainless steel pipe fittings excel in:

- High-pressure systems

- Industrial plumbing

- Large-scale fluid transport

- Corrosive environments

Stainless steel tubing fittings are ideal for:

- Precision instrumentation

- Medical equipment

- Food and beverage processing

- Semiconductor manufacturing

2. Size and Dimension Standards

Pipe fittings follow standardized sizing (NPT, BSP, etc.), while tubing fittings use measurement-based systems. For **stainless steel fittings**, consider:

- Pipe sizes: 1/8″ to 72″ (nominal)

- Tube sizes: 1/16″ to 4″ (actual OD)

3. Pressure and Temperature Ratings

Stainless steel offers excellent performance in both categories, but:

- Pipe fittings typically handle higher pressures (Schedule 40, 80, etc.)

- Tubing fittings provide more precise control in moderate pressure systems

4. Connection Types

Common connection methods for stainless steel pipe fittings:

- Threaded (NPT, BSPT)

- Socket weld

- Butt weld

- Flanged

Popular stainless steel tubing fittings:

- Compression fittings

- Push-to-connect

- Ferrule fittings (like Swagelok)

- Bevel seat connections

5. Material Grades

For stainless steel fittings, consider these common grades:

- 304/304L: General purpose

- 316/316L: Superior corrosion resistance

- 321: High temperature applications

- 904L: Extreme corrosive environments

Installation and Maintenance Factors

1. Ease of Assembly

- Tubing fittings: Often easier to install, especially compression types

- Pipe fittings: May require welding or threading equipment

2. Maintenance Requirements

Both stainless steel pipe fittings and tubing fittings offer:

- Excellent corrosion resistance

- Long service life

- Minimal maintenance needs

However, welded pipe systems are generally more permanent than tube systems with removable fittings.

Cost Considerations

While stainless steel fittings typically cost more than other materials, they provide superior longevity. Compare:

- Initial costs: Tubing systems often cost more per foot but may save on installation

- Long-term value: Both offer excellent ROI in corrosive or high-purity applications

Industry-Specific Recommendations

1. For Industrial Applications:

- Chemical processing: Heavy-duty stainless steel pipe fittings

- Oil and gas: High-pressure pipe systems with welded fittings

2. For Precision Applications:

- Pharmaceuticals: Sanitary stainless steel tubing fittings

- Laboratory: Precision compression fittings

Choosing between tubing and pipe stainless steel fittings ultimately depends on your specific application requirements, budget, and performance expectations. Pipe fittings generally offer superior strength for industrial applications, while tubing fittings provide precision and flexibility for specialized systems.

Post time: Aug-14-2025