Stainless steel thread fittings are essential components in plumbing, industrial, and hydraulic systems. Choosing high-quality fittings ensures durability, leak-proof performance, and resistance to corrosion. However, with many suppliers offering varying grades, how can you identify top-quality stainless steel thread fittings?

1. Check the Stainless Steel Grade

The material grade determines corrosion resistance and strength. Common grades include:

- 304 Stainless Steel: Good for general use, resistant to rust and oxidation.

- 316 Stainless Steel: Contains molybdenum, making it ideal for harsh environments (marine, chemical industries).

- 201 Stainless Steel: Lower-cost alternative but less corrosion-resistant.

**Tip:** Always verify the material certification (ASTM, ANSI, or ISO standards) to ensure authenticity.

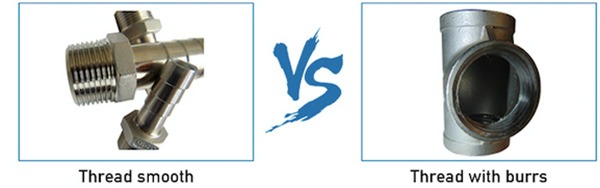

2. Inspect the Surface Finish

High-quality fittings should have:

- Smooth, polished surfaces without cracks, pits, or burrs.

- Uniform threading with no deformities or rough edges.

- No discoloration or rust spots, indicating poor material or storage conditions.

Low-quality fittings often have rough finishes, inconsistent machining, or visible defects.

3. Verify Thread Precision & Compatibility

Proper threading ensures a secure, leak-free connection. Check:

- Thread Standards (NPT, BSP, Metric) – Ensure compatibility with your system.

- Thread Engagement – Fittings should screw together smoothly without excessive force.

- No Cross-Threading – Misaligned threads indicate poor manufacturing.

**Tip:** Use a thread gauge to verify accuracy.

4. Test Corrosion Resistance

Stainless steel should resist rust, but low-quality fittings may fail. Simple tests include:

- Salt Spray Test – Exposure to saltwater should not cause rapid corrosion.

- Magnet Test – Austenitic stainless steel (304, 316) is generally non-magnetic. Strong magnetism suggests a lower-grade alloy.

5. Assess Pressure & Temperature Ratings

Ensure fittings meet your system’s requirements:

- PSI Rating – Must withstand maximum operating pressure.

- Temperature Tolerance – High-quality fittings handle extreme heat/cold without deformation.

**Warning:** Cheap fittings may crack under pressure or high temperatures.

6. Examine Manufacturer Reputation & Certifications

Reliable suppliers provide:

- Material Test Reports (MTRs) – Confirming chemical composition.

- ISO 9001, ASME, or ASTM Certifications – Ensuring quality control.

- Warranty/Guarantee – A sign of confidence in product durability.

Avoid uncertified suppliers with no track record.

Conclusion

To ensure you’re purchasing high-quality stainless steel thread fittings, always:

✔ Verify the material grade (304 or 316 preferred).

✔ Inspect surface finish and threading precision.

✔ Test corrosion resistance and pressure ratings.

✔ Buy from certified, reputable manufacturers.

Investing in premium fittings prevents leaks, failures, and costly repairs in the long run.

Post time: Jun-20-2025